LCA: Sustainability as “substance,” not just “form”

LCA (Life Cycle Assessment) is an internationally recognized method for quantitatively evaluating a product’s environmental impact across its entire life cycle — from raw material extraction to production, use, and disposal.

Rather than simply claiming “made from recycled materials,” LCA quantitatively proves whether that recycling truly has a positive environmental impact. It is a concrete standard for real sustainability.

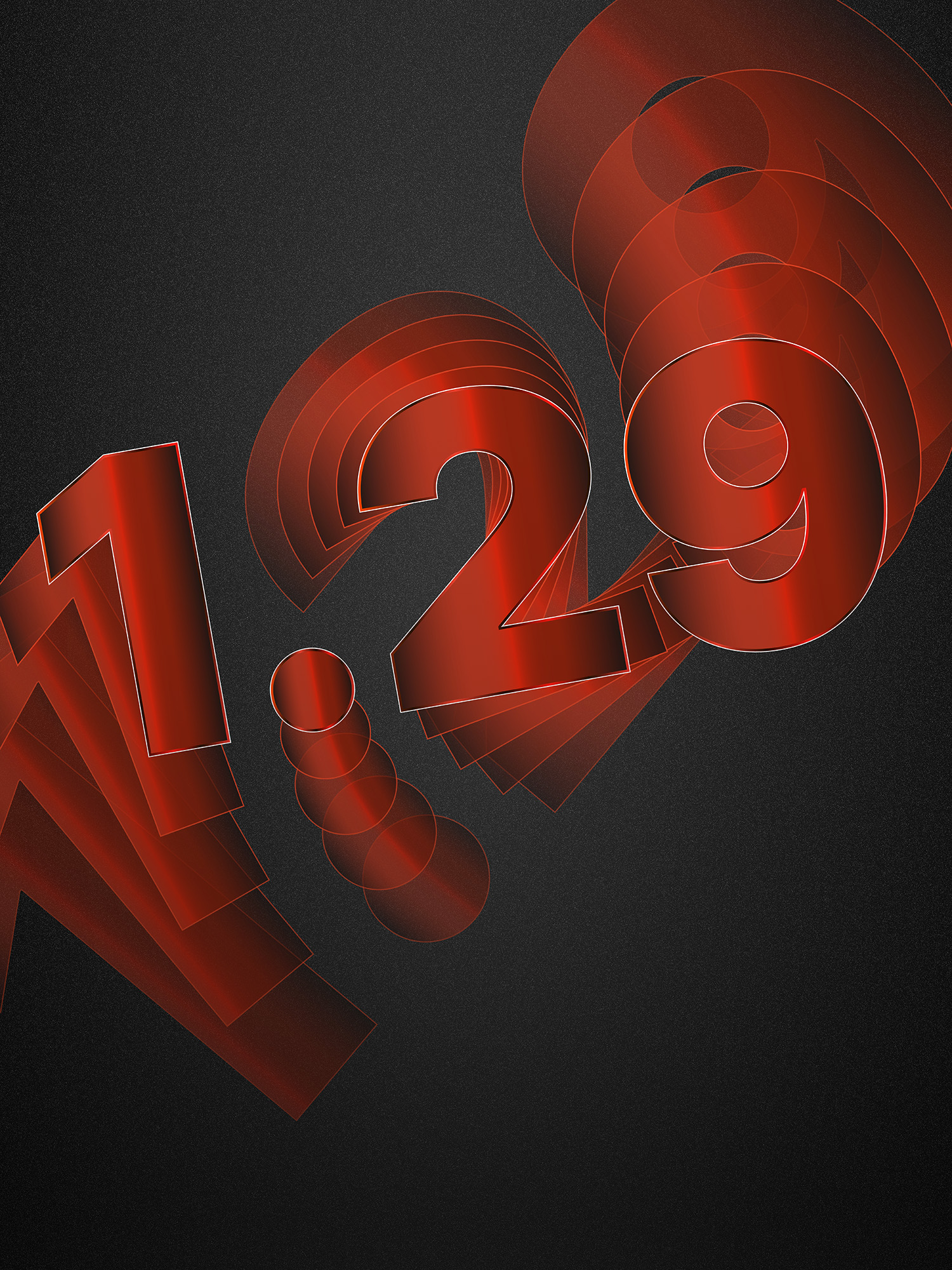

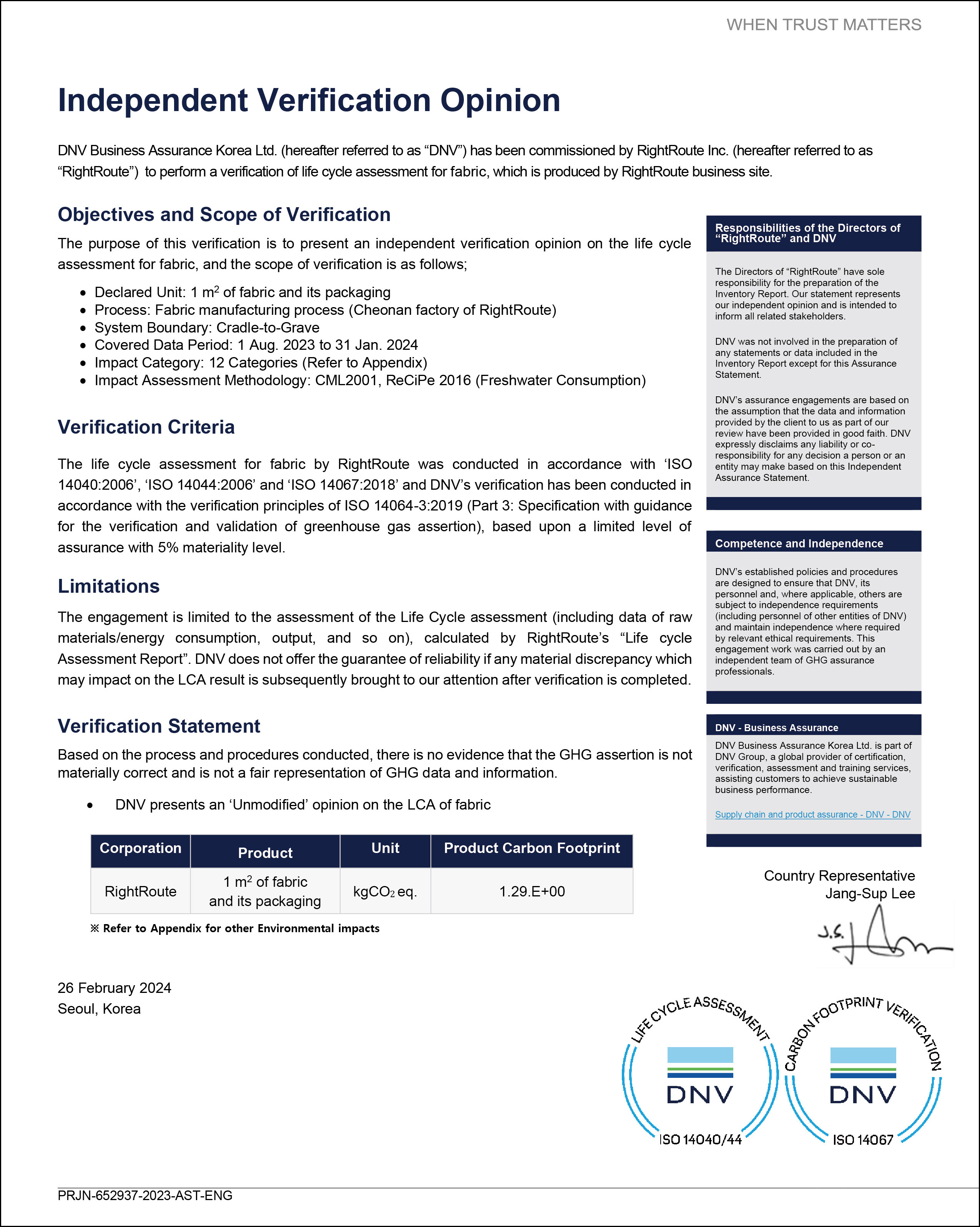

TEXNIC® conducted a formal LCA assessment of its PE laminated fabrics through a certified LCA organization. The results showed a carbon footprint of 1.29 kgCO₂e/㎡.

This figure is significantly lower than commonly cited averages for polyester (3.2 kgCO₂e/㎡) and nylon (3.65 kgCO₂e/㎡).

This means TEXNIC® achieved more than a 60% reduction in carbon emissions per unit area — clear numerical proof of what TEXNIC® calls “eco-innovation as technology.”

This is not just a result limited to a single product. It demonstrates that all TEXNIC® materials, developed through its laminating and slitting technologies, can simultaneously meet high standards for both environmental sustainability and functional performance.

Questions that begin from the structure of technology

TEXNIC® constantly asks itself:

“What exactly is recycling?” “For whom and in what ways is this recycling meaningful?” and “Can sustainability be designed?”

TEXNIC®’s answers are not found in the texture or appearance of its fabrics, but in the very structure of its technology.

From the methods of material bonding, to how remnants are handled, and the systems for end-of-life processing — TEXNIC® embeds sustainability into every stage of its processes.

TEXNIC® believes that the details of its technology must embody the brand’s philosophy itself.

Instangram

Instangram Linkedin

Linkedin